Ngokuthuthuka kancane kancane kokuqwashisa ngemvelo, ama-pallets okhuni ahoxa kancane kancane esigabeni somlando. Ngokuhambisana nokukhuphuka kwamanani ezinkuni, inzuzo yabo yokuncintisana ngentengo kancane kancane iyancipha, futhi ama-pallets epulasitiki aseqalile ukufaka esikhundleni se-pallets yokhuni. Namuhla, ama-pallet epulasitiki asetshenziswa ezimbonini ezihlukahlukene, kodwa kungakanani okwaziyo ngamapulangwe epulasitiki?

1.Impahla

Njengamanje, kunezigaba ezimbili ezinkulu zezinto ezisetshenziswayo emakethe ye-pallet yepulasitiki: i-PP ne-PE. Amaphalethi epulasitiki enziwe ngalezi zinto ezimbili ngayinye inezinzuzo zayo kanye nokubi, futhi angakwazi ukuhambisana ekusetshenzisweni okungokoqobo. Kalula nje, ama-pallets epulasitiki enziwe nge-PE awakwazi ukumelana nokubanda futhi asetshenziswa kabanzi embonini yokudla, ngoba ukudla okuningi kufanele kugcinwe endaweni ebandayo. Amaphalethi epulasitiki enziwe ngezinto ze-PP amelana kakhulu nokuwa, anokumelana nomthelela onamandla, futhi mancane amathuba okuthi onakaliswe ngenxa yokusebenza okungalungile.

2. Izinto zokwakha ezintsha nezinto ezigaywe kabusha

Amaphalethi epulasitiki ayimikhiqizo evuselelekayo. Amaphalethi epulasitiki asetshenzisiwe azogaywa kabusha futhi enziwe kabusha abe izinto ezingavuthiwe, okuvame ukubizwa ngokuthi izinto ezigaywe kabusha. Ngisho noma ama-pallet epulasitiki enziwe ngezinto ezintsha ehlala isikhathi eside, amakhasimende ahlukene azoba nezidingo ezahlukene. Ezinkampanini ezisetshenziswa isikhathi esifushane kuphela futhi zinezidingo eziphansi zokuthwala umthwalo, ama-pallets epulasitiki enziwe ngezinto ezintsha awabizi. Ngokuvamile, umbala we-pallet yepulasitiki ungasetshenziswa ukunquma ukuthi into entsha noma into egaywe kabusha. Umbala wephalethi lepulasitiki lezinto ezintsha uyagqama, kuyilapho izinto ezigaywe kabusha zizoba mnyama ngombala. Vele, kuzoba nezingxube, ezidinga izindlela zobuchwepheshe ezithe xaxa zokwahlulela.

3. Ukuthwala umthwalo kanye nesimo sefonti

Umthamo wokuthwala umthwalo wamaphalethi epulasitiki ikakhulukazi uncike ezintweni kanye nenani lezinto ezingavuthiwe, isitayela sephalethi kanye nokuthi kukhona yini amapayipi ensimbi eyakhelwe ngaphakathi. Uma nje ingakwazi ukuhlangabezana nezidingo zenkampani ngokwayo, isisindo se-pallet ngokwayo kufanele kube lula ngangokunokwenzeka, okungeyona nje elula ukuphatha, kodwa futhi igcina izinto zokuhamba. izindleko. Ifonti yephalethi inqunywa ngokuyinhloko ngokwezindawo ezihlukene zokusetshenziswa. Kungakhathaliseki ukuthi i-forklift yomshini noma i-forklift ye-manual, kungakhathaliseki ukuthi idinga ukufakwa i-palletized, noma ngabe idinga ukufakwa eshalofini, njll. zonke izici eziyinhloko ekukhetheni ifonti ye-pallet.

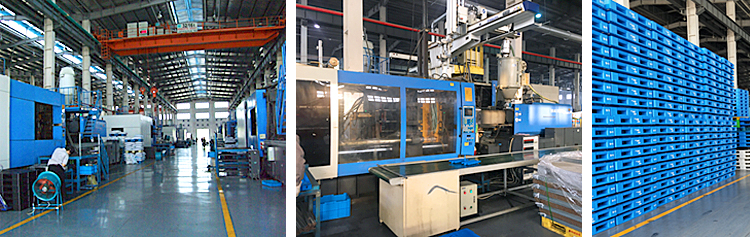

4.Inqubo yokukhiqiza

Njengamanje, izinqubo eziyinhloko zama-pallets epulasitiki ziwukubumba umjovo nokubunjwa kokushaywa. Ukubumba komjovo ukubumba komjovo we-thermoplastic, okwakhiwa ngokujova izinto ezingavuthiwe ezincibilikisiwe endaweni yokubumba engaguquki. Kuyinqubo yokukhiqiza evame kakhulu. Amaphalethi ajwayelekile ayisicaba kanye namaphalethi egridi abunjwa ngomjovo. Amaphalethi epulasitiki ezitayela nezimo ezahlukene akhiqizwa ngokwezidingo ezahlukene zamakhasimende. Ukubumba i-Blow kubizwa nangokuthi ukubumba okungenalutho. Kuvamise ukuba nezimbobo zokubumba ezivuthela ngaphezulu kwephalethi yokubumba i- blow, kanti phakathi nendawo ye-pallet ayinalutho. Inqubo yokubumba igalelo ingakhiqiza kuphela amaphalethi anezinhlangothi ezimbili, futhi isiqondiso sokungena ngokuvamile siqondiswa kabili. Ngokuvamile, intengo yamaphalethi abunjwe ngokushaywa iphezulu kunaleyo yamaphalethi abunjwe ngomjovo.

Ama-pallet epulasitiki athandwa ngamabhizinisi emikhakheni ehlukahlukene ngenxa yokusebenziseka kwawo, ukuvikelwa kwemvelo nokusebenza kahle. Ngokuthuthuka okuqhubekayo kwe-inthanethi Yezinto, ukusetshenziswa kwama-smart pallets ekugcineni kuzoba umkhuba wokuthuthuka. Ama-chips afakwe kuma-pallets epulasitiki ukuwavumela ukuthi aqoqe ulwazi. Ukudluliswa, ukulandelela indawo, ukuhlukanisa kanye nokuhlukaniswa kuhlanganiswe ukuze kuzuzwe ukuphathwa okubonakalayo kwe-supply chain.

Isikhathi sokuthumela: Apr-26-2024